Working with Artificial Feature Magnets

Working with Artificial Feature Magnets

Before mapping the area, you need to place Artificial Feature Magnets across the assembly part that you will work with.

Here you will learn why the magnets are needed, and also how and when to place them.

Why magnets are needed

The requirement for the AF magnets occurs because while mapping, the camera investigates the environment to make the tracking accurate.

It looks for the unique features to track, but a steel shop doesn’t have enough features that are unique.

That’s why we ask you to place the AF magnets throughout the assembly to artificially create a rich environment for the camera.

Time to place magnets

The most convenient time to do it is along with placing a QR code target, as the QR code scanning and mapping the area should go one after another without interruption.

Click here to learn more about Placing and Scanning QR target.

How to place magnets

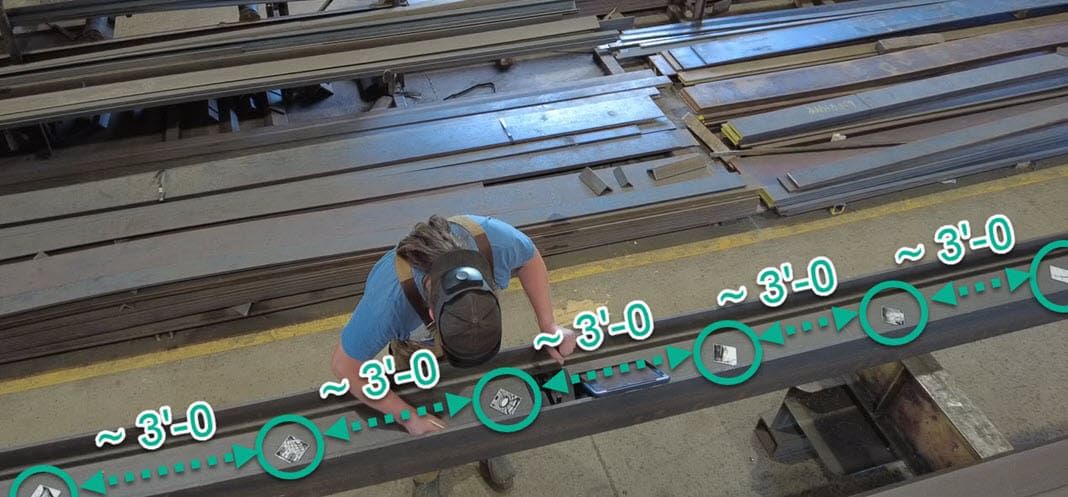

Place artificial feature magnets every 3′-0 (approximately).

After mapping, the magnets cannot be adjusted or moved because they have been recorded and serve as tracking points to recognize the rest of the environment.

You can remove the magnets, but you risk that the accuracy will be affected.

The same is applicable to the constantly moving objects or people within camera range while mapping. Since the camera captures any unique features, such objects and people may become a part of the unique environment, working as anchors.

And if such anchors will move after mapping, it will affect the precision of the map.

So, please avoid people/moving objects while mapping within the camera range or reduce their presence, if possible.