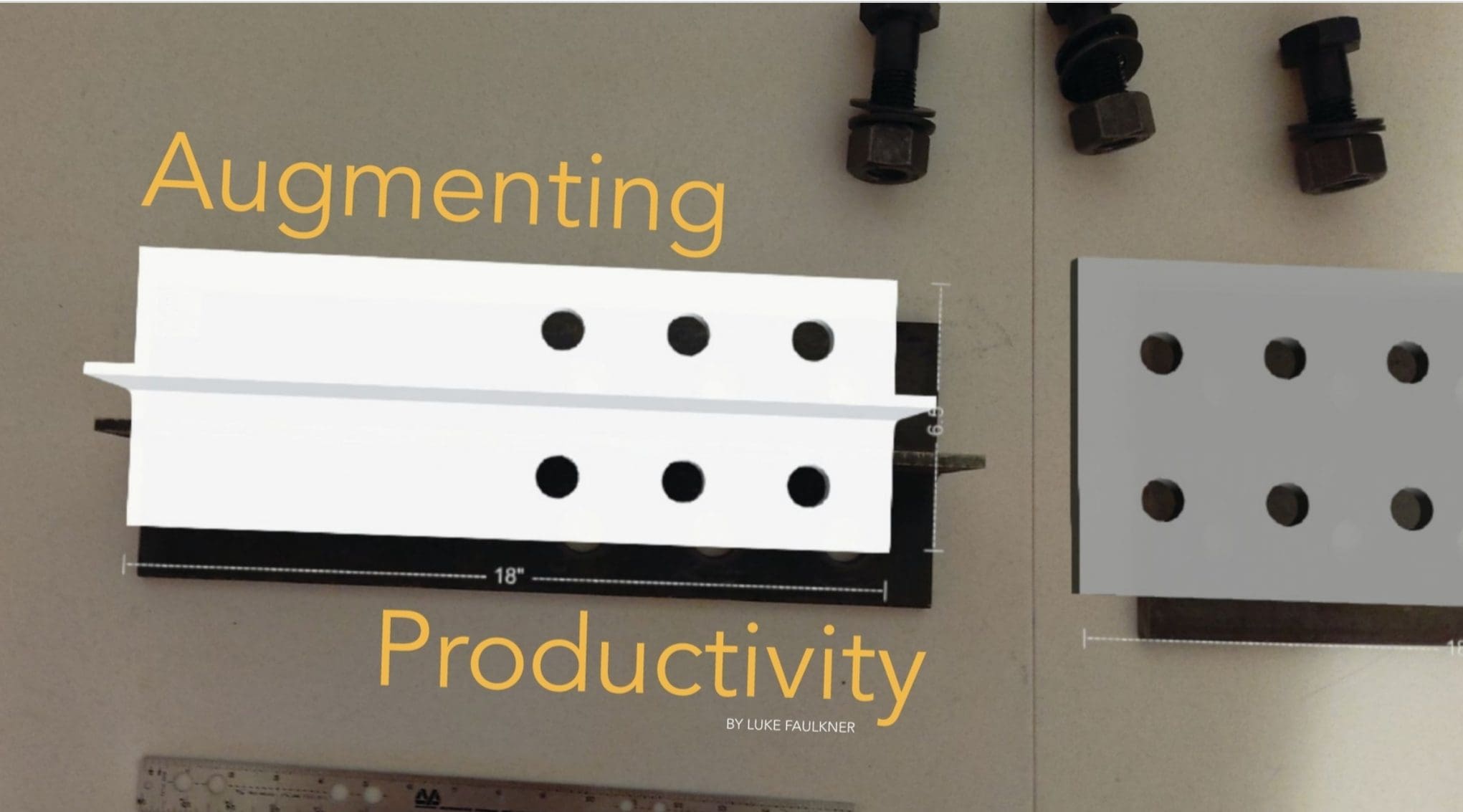

Last month we discussed the introduction of technology into the shop workflow. Just after that article was written, the June 2021 issue of Modern Steel came out with an article on Augmented Reality (AR) in steel construction. The use of AR is seen as one way steel fabrication shops can contribute to increasing construction velocity (“Need for Speed” initiative).

While the application of AR in the steel industry is relatively new, the technology has been evolving for several years. With a greater emphasis on 3D modelling and the advancements in mobile computing technology, the time is right to explore this technology.

Click on the article below to read more:

The author brings up some valid points about accuracy. Currently, we find an accuracy of 3/16″ to 1/4″ or 3-6 mm is possible. Although it is not the 1/16″ tolerance necessary for the automated layout tool of the future, as mentioned in the article, it is still an extremely useful tool for understanding part placement prior to fitting and inspection of parts after fitting.

Most errors made by fabricators are in misreading measurements or transposing numbers, and these gross errors are easily caught with the existing level of accuracy. It is important to understand that AR technology is an additional tool to help with training, visualization, placement and inspection. Until the shop goes full automation, there will always be a human element that can easily be checked with augmented reality. And even then, someone still has to check the machines are doing it correctly!!!

Understanding and utilizing these tools now and integrating them into your fabricator’s workflow will pay large dividends now and into the future when these tools will be commonplace and indispensable.